SCHOLARSHIP PROGRAM FOR HIGH SCHOOL STUDENTS

Monday, February 20, 2023

During December 2022, the company HBIS SERBIA opened a competition for awarding SCHOLARSHIPS to students of the I, II, III and IV grades of the Smederevo Technical School, attending the following courses: electrical power technician, electrician, locksmith-welder and internal transport operator. The main goal of this company project is attracting young people long-term, with the desire to provide them with support during their high school education.

In February 2023, after the scholarship competition is closed, 26 students from Smederevo Technocal School and one student from Railway Technical School in Belgrade – course: towing technician, signed individual contracts, accompanied by their parents.

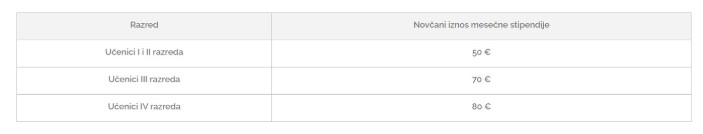

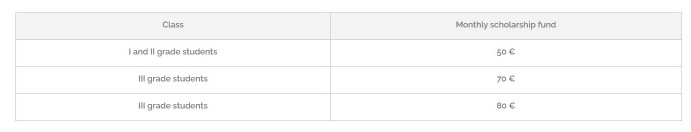

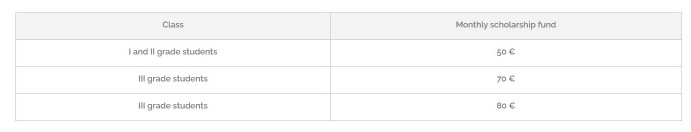

Monthly scholarship funds are different depending on the class they attend:

Dragana Jovanović, Head of the Labour Relations and Legal Procedure group, informed the children and their parents about the most important thing: it is necessary for students to have a GPA of at least 3, which means at least good grade. That is one of conditions that has to be met.

When the students finish their education, the factory will offer them employment within three months. In case that, after they finish their education, the scholarship holder, who is offered employment at HBIS GROUP Serbia Iron & Steel d.o.o., declines, they are obliged to return the full amount of funds received on behalf of the scholarship. After completing education, the scholarship holder is obliged to spend at least double period of time for which they received the scholarship.

During the compulsory practice, and in accordance with the program of the Technical School, the children are provided with transportation, food and adequate PP equipment. Through mentorship program, the time spent in practice will provide them with the possibility of acquiring skills and knowledge that will enable them to be prepared to independently organise their work in the future and master necessary techniques.

“I would like to wish you a happy education and good success in school. And when you finish your education, I hope that we will invite you to work here and be a part of our team. Steel Plant is huge and there is room for various professions, and yours match our needs. Today, after signing the contract, you become the scholars of HBIS Serbia. I congratulate you once again and wish you luck”, said Vladimir Petrović, Head of Training Group in Human Resources Department, on this occasion.

Before the joint photo shoot in the factory, we asked some of the students whose parents work in the factory, what the decision they made and the contract they signed mean for them.

Marko Mitrović, a third-year student, studying for internal transport means operator, has a GPA of 3.80. “This is an important date for me. I know that I have a secured job after school and that is really good. I would like to get a job first and then, maybe, go for higher education, we will see. My father Dragan works in PORD, I have been on practice here and I like a lot of things here”. Ognjen Todorović from Smederevo is currently in his second year, studying for internal transport operator. He has a GPA of 4.30. “My father told me a lot about the factory and that made me want to work here. I am impressed by what I saw, I realize that the factory is huge and I think working in it would be a great challenge for me.” Đorđe Vasić, who is in his fourth year, studying for “energy power technician”, with GPA 3.50. “I grew up hearing stories about the steel plant and it is normal that I got the wish to work here as well. This scholarship is an additional motivation for me and I hope to live up to the expectations of the people who help us.” His father Dobrica Vasić, a manager in Electrical Maintenance in CM, says that he supports his son: “I have surely had an impact on him. My father earned his pension in this factory, I have been working here for 35 years and I wanted one of my sons to try to work here. I think this is a serious and an ideal company for a beginner. A lot of things are regulated by law, and the most important thing is that relations are regulated, CA is respected and you know what is your status. There is a lot to see and learn from experienced colleagues.”

We congratulate the young scholars and wish them lots of luck in continuing their education and gaining knowledge!

SCHOLARSHIP PROGRAM FOR HIGH SCHOOL STUDENTS

Monday, February 20, 2023

During December 2022, the company HBIS SERBIA opened a competition for awarding SCHOLARSHIPS to students of the I, II, III and IV grades of the Smederevo Technical School, attending the following courses: electrical power technician, electrician, locksmith-welder and internal transport operator. The main goal of this company project is attracting young people long-term, with the desire to provide them with support during their high school education.

In February 2023, after the scholarship competition is closed, 26 students from Smederevo Technocal School and one student from Railway Technical School in Belgrade – course: towing technician, signed individual contracts, accompanied by their parents.

Monthly scholarship funds are different depending on the class they attend:

Dragana Jovanović, Head of the Labour Relations and Legal Procedure group, informed the children and their parents about the most important thing: it is necessary for students to have a GPA of at least 3, which means at least good grade. That is one of conditions that has to be met.

When the students finish their education, the factory will offer them employment within three months. In case that, after they finish their education, the scholarship holder, who is offered employment at HBIS GROUP Serbia Iron & Steel d.o.o., declines, they are obliged to return the full amount of funds received on behalf of the scholarship. After completing education, the scholarship holder is obliged to spend at least double period of time for which they received the scholarship.

During the compulsory practice, and in accordance with the program of the Technical School, the children are provided with transportation, food and adequate PP equipment. Through mentorship program, the time spent in practice will provide them with the possibility of acquiring skills and knowledge that will enable them to be prepared to independently organise their work in the future and master necessary techniques.

“I would like to wish you a happy education and good success in school. And when you finish your education, I hope that we will invite you to work here and be a part of our team. Steel Plant is huge and there is room for various professions, and yours match our needs. Today, after signing the contract, you become the scholars of HBIS Serbia. I congratulate you once again and wish you luck”, said Vladimir Petrović, Head of Training Group in Human Resources Department, on this occasion.

Before the joint photo shoot in the factory, we asked some of the students whose parents work in the factory, what the decision they made and the contract they signed mean for them.

Marko Mitrović, a third-year student, studying for internal transport means operator, has a GPA of 3.80. “This is an important date for me. I know that I have a secured job after school and that is really good. I would like to get a job first and then, maybe, go for higher education, we will see. My father Dragan works in PORD, I have been on practice here and I like a lot of things here”. Ognjen Todorović from Smederevo is currently in his second year, studying for internal transport operator. He has a GPA of 4.30. “My father told me a lot about the factory and that made me want to work here. I am impressed by what I saw, I realize that the factory is huge and I think working in it would be a great challenge for me.” Đorđe Vasić, who is in his fourth year, studying for “energy power technician”, with GPA 3.50. “I grew up hearing stories about the steel plant and it is normal that I got the wish to work here as well. This scholarship is an additional motivation for me and I hope to live up to the expectations of the people who help us.” His father Dobrica Vasić, a manager in Electrical Maintenance in CM, says that he supports his son: “I have surely had an impact on him. My father earned his pension in this factory, I have been working here for 35 years and I wanted one of my sons to try to work here. I think this is a serious and an ideal company for a beginner. A lot of things are regulated by law, and the most important thing is that relations are regulated, CA is respected and you know what is your status. There is a lot to see and learn from experienced colleagues.”

We congratulate the young scholars and wish them lots of luck in continuing their education and gaining knowledge!